Coordination in construction industry is one of the key issues as it is faster evolving industry and it is obvious that the issue of communication between various disciplines takes important role. It is one of the important points or the key factor which significantly influences the success of the building project that is MEP (Mechanical, Electrical, and Plumbing) coordination.

In the blog post that we will do, we are going to look at the notion that is the KEY reason for the MEP coordination to exist in this world and then we are going to investigate the best practices for contractors, engineers, and designers as well who do the optimizing processes.

What is MEP Coordination?

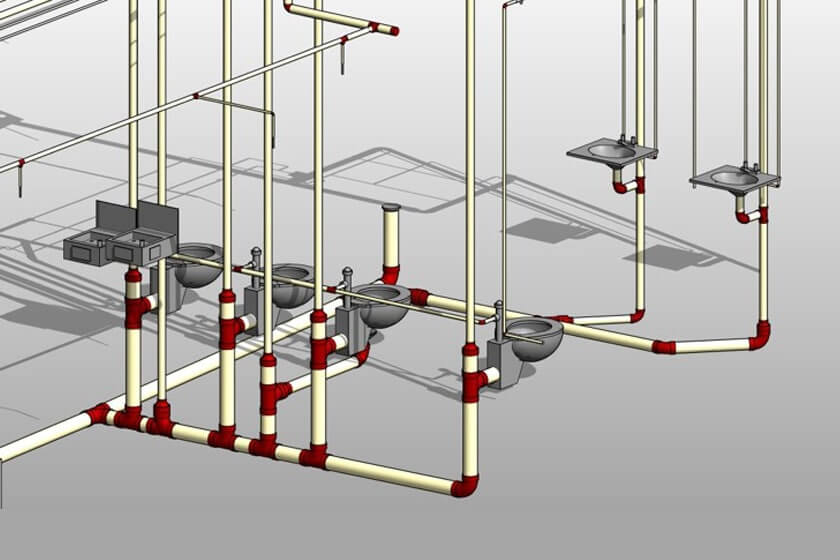

The MEP coordination upshots are the precise scheduling, design and uniformity of the building’s mechanical systems, electrical and plumbing systems. It brings to the fore the fact that the various components work together without competing or reversing the efficiency. In order to ensure smooth coordination, project teams can closely adjust these systems at the earliest stage of the design phase which cover unanticipated cost, delay, and also insecure safety during the construction.

Since MEP BIM Coordination in Construction is a crucial element in any construction project, it is vital for every stakeholder involved to recognize the importance of this process and work together harmoniously for its effective implementation.

The Importance of MEP Coordination

Effective MEP coordination offers numerous benefits that directly contribute to the success of a building project:

Improved Building Efficiency: generation failed. Please try again at disable. Support staff if it’s ongoing.

MEP coordination allows the maximalization of building systems by providing optimal solutions, consequently, more efficient systems and less energy is consumed. Through the input of all mechanical, electrical, and plumbing components in one plan, construction schedules will be avoided, the amount of construction interference will be minimized and one place will be saved.

Cost Savings: Indisputably, the efficient collaboration of the MEP brings about reduction in the construction costs through prevention of the collision between different systems that maybe necessitate repairs or delays. It is also a tool that can detect opportunities to lower costs through coordinated routes and systems.

Enhanced Safety: Through cooperation of the MEP systems, issues related to safety can be spotted and eliminated for the sake of design in the early stages. This is all about unifying all the building factors be it in the form of electrical, plumbing, and ventilation so that they function together smoothly and are in accordance with safety codes and regulations.

Streamlined Construction Process: Teams can streamline construction procedures as coordination in MEP helps eliminate issues and possible delays from project opening.

Best Practices for MEP Coordination

Now that we understand the importance of MEP coordination let’s explore some best practices for optimizing this process:

Early Collaboration: The MEP coordination effectiveness depends greatly on the amount of early, joint work. MEP contractors, designers, and engineers must collaborate. With the use of co-design concepts, all stakeholders can be brought into the early design stages. This allows any conflicts and other issues to be anticipated and dealt with before the actual construction process begins.

Utilize BIM Technology: The BIM technology enables drafting 3D model of the whole installation that brings all building’s systems together. This is subsequent for project teams to emulate how different systems are connected and to find out which problems may arise and how to prevent them from happening before the construction kicks off.

Regular Communication: Effective communication is essential for an efficient teamwork on the Mechanical, Electrical and Plumbing areas of the project. In order to eliminate uncertainty and obstacles such as conflicts the open communication channel is developed among all parties which is crucial to keep everyone in tune.

Continuous Coordination: MEP system coordination should be a design phase which continues throughout the build. As such changes or editing are being done, the MEP systems shall have to be closely corresponding and be updated in a recurring manner.

Conclusion

MEP coordination as a very valuable feature of the design process aimed to create better and stronger buildings. Adopting these standards early communication, BIM technology application and status updates can only make the process of designing and building be even better and result in the efficiency realization. With the growing development of the building industry, functional MEP BIM modeling is, as a result, the most important aspect contributing to construction success.

Therefore, all the stakeholders concerned should view this as an utmost important issue and giving it the rightful investment to get the best output. Accordingly, we will ensure all our efforts are in one direction and unleash our greatest potential to achieve perfection in every building we work on.